Featured Work

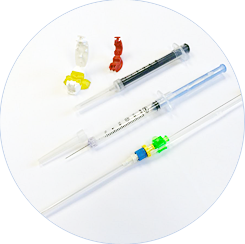

Medical Plastics

We can help you design custom plastic parts and get them into production. Shown are a complex IV, an automatic needle retracting syringe, and a few complicated small plastic medical retainers. We have seven seats of SolidWorks. We have ISO 9001 and 13485 to better serve this market.

PCBA Design

If the product on your wish list includes electronics we can help. Shown is a stack of circuit boards we have designed for various markets including medical, consumer and commercial products. RF, embedded systems, power supplies, bluetooth, wifi are among the areas we have depth. We have three seats of high end schematic capture, layout, and simulation software.

Consumer Products

When you need Industrial Design, plastic and part design, electronics, and consideration of manufacturing processes quality, we can help.

Complex Consumer Product

This product had 20 injection molded parts, a complex PCBA, lots of FW and a real need for detailed design to match the client's desire for a very high end device. All the work was done in-house.

We can be your team or help your team.

Here is an example of some of the products we have designed recently. We have a significant mechanics design team of six mechanical engineers.

Firmware and Software

We have an active in-house embedded team that has worked with radios, networks and many types of microcontrollers.

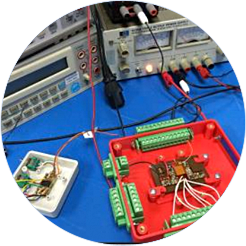

Engineering Support

After the design is 'done' sometimes the heavy lifting begins as the product moves into production. Tooling, debugging, complicated test fixtures and documentation are common tasks we can help with. Shown here is a medical implant PCBA under test.

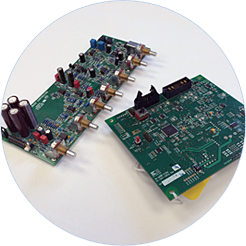

Diverse electronic Experience

Shown are some recent projects. One is an 'old fashion' low noise analog design for a musical instrument (sometimes that industry likes the old look.) The other is a typical PCBA with a microcontroller and a collection of analog and digital inputs.